联系 - 热线

联系 - 热线

0531-69953988

联系 - 热线

联系 - 热线

驰放气发电机组:高低瓦斯浓度发电效率的对比

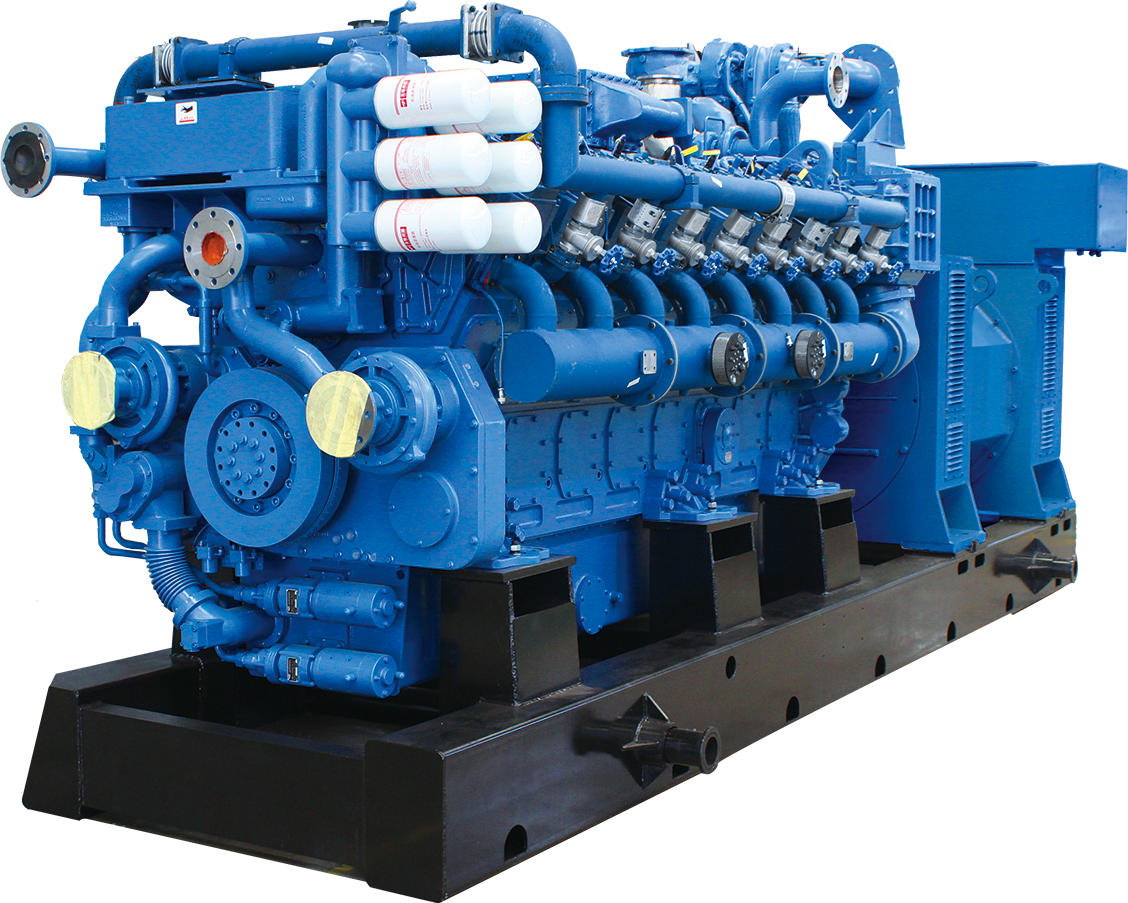

燃气内燃发电机组

Gas internal combustion generator set

燃气内燃发电机组分为高浓度瓦斯发电机组和低浓度瓦斯发电机组,高浓度瓦斯发电机组要求甲烷含量在25%以上;低浓度瓦斯发电机组要求甲烷含量在12%-25%;依据瓦斯浓度状况选择发电机组型号,低瓦斯发电机组一般选择|IMWfc右,高瓦斯发电机组一般选择2MWfc右。高瓦斯发电机组发电效率比低瓦斯发电机组发电效率略高。瓦斯发电机燃料能量约35%被机组转变为电能,约30%随废气排出,25%被发动机冷却水带走。

Gas internal combustion generator sets are divided into high concentration gas generator sets and low concentration gas generator sets. High concentration gas generator sets require a methane content of at least 25%; The low concentration gas generator unit requires a methane content of 12% -25%; Select the generator set model based on the gas concentration situation. Low gas generator sets are generally selected to the right of IMWfc, while high gas generator sets are generally selected to the right of 2MWfc. The power generation efficiency of high gas generator sets is slightly higher than that of low gas generator sets. About 35% of the fuel energy of the gas generator is converted into electrical energy by the unit, about 30% is discharged with exhaust gas, and 25% is taken away by the engine cooling water.

低浓度瓦斯发电机组采纳电控燃气混淆器技术,能够自动控制空燃比,以适应瓦斯的浓度变化,将瓦斯浓度调整9%,此时瓦斯爆炸反应最完整,瓦斯、氧气氧化反应完整,实现零氧均衡,此时爆炸威力也最大,做收效率最高。上下瓦斯发电最大的差别:低浓度处于爆炸极限内的甲烷在进入机组前的过程中是不一样意设置储气罐和加压机,而高浓度瓦斯在输送过程中可不设计瓦斯安全输送系统。

The low concentration gas generator set adopts electric control gas mixer technology, which can automatically control the air-fuel ratio to adapt to changes in gas concentration. By adjusting the gas concentration by 9%, the gas explosion reaction is most complete, and the oxidation reaction of gas and oxygen is complete, achieving zero oxygen balance. At this time, the explosion power is also the highest and the collection efficiency is the highest. The biggest difference between upper and lower gas power generation is that methane with low concentration within the explosive limit does not require the installation of gas storage tanks and compressors before entering the unit, while high concentration gas does not require the design of a gas safety conveying system during transportation.

、上下瓦斯发电工艺及差别

Upper and lower gas power generation processes and differences

瓦斯经过安全输送系统(雾化水系统、水封阻火器、安全阀等)的传称,瓦斯预办理系统对气体杂质、液态水的过滤随和体温度的调控,进入机组内先进行预混淆,以后由涡轮增压器增压、中冷器降温、在缸内用火花塞点火,焚烧后高温高压气体带动证体活塞和曲抽坛OCS.COM动,推进发动机做功,将机械能转变为电能。详尽工艺流程见以下列图:

Gas is transported through a safety conveying system (atomization water system, water seal flame arrester, safety valve, etc.), and the gas pre-treatment system filters gas impurities and liquid water while regulating body temperature. Before entering the unit, it undergoes pre mixing, and then is pressurized by a turbocharger, cooled by an intercooler, and ignited with spark plugs in the cylinder. After incineration, the high-temperature and high-pressure gas drives the piston of the body and the curved extraction tank OCS.COM to move, pushing the engine to do work and converting mechanical energy into electrical energy. The detailed process flow is shown in the following diagram:

瓦斯发电工艺系统。瓦斯发电工艺主要包含11项系统,热力系统、燃料供给系统、余热利用系统、瓦斯输送安全装置系统、除灰系统、水办理系统、供水系统、并网工程、电气系统、热工控制系统、隶属生产工程、烟气脱硫脱硝系统。各工艺系统详尽状况介绍以下:热力系统:瓦斯与空气在集装箱式内燃机发电机机组进气进口处混淆后,进入涡轮增压器增压,再经过中冷器冷却,经过进气管由进气门控制进入气缸,经火花塞点火爆炸氧化,产生动力驱动发电机曲轴旋转,曲轴将动力传给沟通发电机,变换成电能输出。主要设备包括燃气发动机和沟通发电机,以及配套的管路和设备。

Gas power generation process system. The gas power generation process mainly includes 11 systems, including thermal system, fuel supply system, waste heat utilization system, gas transportation safety device system, ash removal system, water treatment system, water supply system, grid connected engineering, electrical system, thermal control system, subordinate production engineering, and flue gas desulfurization and denitrification system. The detailed description of each process system is as follows: Thermal system: Gas and air are mixed at the inlet of the container type internal combustion engine generator unit, then enter the turbocharger for boosting, and are cooled by the intercooler. They enter the cylinder through the intake pipe controlled by the intake valve, and are ignited by the spark plug for explosive oxidation, generating power to drive the generator crankshaft to rotate. The crankshaft transmits the power to the communication generator and converts it into electrical energy output. The main equipment includes gas engines and communication generators, as well as supporting pipelines and equipment.

燃料供给系统:矿井瓦斯从井下煤层中,经过瓦斯泵站抽采后,抽排到地面,由瓦斯输送管道经过泵送、离心脱水、制冷脱水等系列安全办理举措,供给瓦斯发电机组。主要工程包含:瓦斯预办理土建、罗茨风机设备及安装工程。

Fuel supply system: Mine gas is extracted from the coal seam underground through a gas pump station and discharged to the surface. It is then transported through gas pipelines through a series of safety measures such as pumping, centrifugal dehydration, and refrigeration dehydration, and supplied to gas generators. The main projects include: gas pre-treatment civil engineering, Roots blower equipment and installation engineering.

余热利用系统:发电机组尾气净化后排烟温度高达400-600C,直接对空排放将造成热能浪费,为把有效热能充足利用,在排烟简处设置蒸汽锅炉或许余热锅炉,锅炉将热源供给给用户,解决工业场所冬天取暖供热问题。主要设备包含余热锅炉和配套管路设备。

Waste heat utilization system: After purifying the exhaust gas of the generator set, the exhaust temperature can reach 400-600C. Directly discharging it into the air will cause waste of heat energy. In order to fully utilize the effective heat energy, a steam boiler or waste heat boiler is installed at the exhaust section. The boiler supplies heat source to users, solving the heating problem of industrial plants in winter. The main equipment includes waste heat boilers and supporting pipeline equipment.

瓦斯安全输送系统:瓦斯经过瓦斯泵站,增压机增压泵送进入发电机组,沿途需要设置水封阻火器、水雾输送系统、干式阻火器等防爆阻爆安全设备,保证瓦斯输送安全。

Gas safety transportation system: Gas is pumped into the generator set through a gas pump station and a booster pump. Explosion proof and explosion-proof safety equipment such as water sealed flame arresters, water mist transportation systems, and dry flame arresters need to be installed along the way to ensure the safety of gas transportation.

除灰系统:在瓦斯输送管道中增添一道滤网,将瓦斯中的粉尘和杂质等固体颗粒物过滤,保证瓦斯纯度和质量。

Ash removal system: Add a filter screen in the gas conveying pipeline to filter solid particles such as dust and impurities in the gas, ensuring the purity and quality of the gas.

水办理及供水系统:场所内生活水硬度高,水中钙、镁含量高,简单腐化机组和锅炉设备,不利于余热锅炉和机组冷却循环水使用,需要将水进行融化办理,融化后利用水泵供给给机组冷却系统和采暖系统。主要工程包含:水融化车间、水泵、水箱等配套设备。

Water treatment and supply system: The hardness of domestic water in the premises is high, and the calcium and magnesium content in the water is high, which easily corrodes the units and boiler equipment, and is not conducive to the use of waste heat boilers and unit cooling circulating water. It is necessary to melt the water and supply it to the unit cooling system and heating system through a water pump after melting. The main project includes supporting equipment such as water melting workshop, water pump, water tank, etc.

主要工程包含:水融化车间、水泵、水箱等配套设备。并网工程:瓦斯发电除供给7%的厂区自觉子用以外,富饶电量所有上网,接入邻近高压变电站并网运转,与国家电力联网。主要设备包含变压器和配套并网设备电气系统:发电站所有电气设备的运转状况需要形成自动监控、丈量、保护的电气系统,经过通讯技术与发电站管理系统连结,实现电气自动化。主要工程包含:主控系统、上下压开关、电缆、照明、防雷接地等电气设备。

The main project includes supporting equipment such as water melting workshop, water pump, water tank, etc. Grid connected project: Gas power generation not only supplies 7% of the plant's self owned electricity, but also connects all abundant electricity to the grid and nearby high-voltage substations for grid connection and operation, and is connected to the national power grid. The main equipment includes transformers and supporting grid connected electrical systems: the operation status of all electrical equipment in the power station needs to form an automatic monitoring, measurement, and protection electrical system, which is connected to the power station management system through communication technology to achieve electrical automation. The main project includes: main control system, upper and lower pressure switches, cables, lighting, lightning protection and grounding electrical equipment.

热工控制系统:为了提升电站自动化水平,保证机组安全经济运转,提升效率,减少运转人员的劳动强度,需要对瓦斯发电机组设备推行集中控制,保证机组安全运转。主要工程包含热工控制、微机监控、火灾报警、工业电视系统等。

Thermal control system: In order to improve the automation level of the power station, ensure the safe and economical operation of the unit, enhance efficiency, and reduce the labor intensity of the operating personnel, it is necessary to implement centralized control of the gas generator equipment to ensure the safe operation of the unit. The main projects include thermal control, microcomputer monitoring, fire alarm, industrial television system, etc.

隶属生产系统:瓦斯发电工程除主要生产系统工程以外,还需配套建设消防系统、室外给排水系统、场所土方、围护等及其余隶属生产系统,效力于主要生产系统。烟气净化系统;瓦斯爆炸做功会产生粉尘、氮氧化合物等有害气体,为保证尾气排放知足国家环保要求,定对排放的废气进行净化办理。在排气管道设置尿素催化剂喷嘴,催化剂在高温作用下分解成NH货口H2Q与尾气混淆后产生化学反应,产生氮气和水排到大气中,减少大气污染。主要设备包含:尿素溶液储罐、输送装置、计量装置等其余配套设备上下瓦斯发电工艺差别。高瓦斯发电与低瓦斯发电工艺系统根本

Subordinate production system: In addition to the main production system engineering, gas power generation projects also need to be equipped with supporting fire protection systems, outdoor water supply and drainage systems, site earthworks, enclosures, and other subordinate production systems to serve the main production system. Smoke purification system; Gas explosions can produce harmful gases such as dust and nitrogen oxides. In order to ensure that exhaust emissions meet national environmental requirements, it is necessary to purify the discharged exhaust gas. Install a urea catalyst nozzle in the exhaust pipe. The catalyst decomposes into NH and H2Q under high temperature, which reacts with the exhaust gas to produce nitrogen and water that are discharged into the atmosphere, reducing air pollution. The main equipment includes: urea solution storage tank, conveying device, metering device, and other supporting equipment, with differences in gas power generation process between the upper and lower parts. The fundamental process systems for high gas power generation and low gas power generation

同样,高瓦斯发电没有瓦斯安全输送系统,低浓度瓦斯地面安全输送

Similarly, high gas power generation does not have a gas safety transmission system, and low concentration gas is safely transported on the ground

技术目前主要有三种方式,即细水雾混淆安全输送装置(如胡底电厂)、瓦斯输送自动喷粉抑爆装置(如岳城电厂)、两相流安全输送装置。其余电力系统、燃料供给系统、余热利用系统等系统根真相像。

There are currently three main methods of technology, namely fine water mist mixing safety conveying device (such as Hudi Power Plant), gas conveying automatic powder spraying explosion suppression device (such as Yuecheng Power Plant), and two-phase flow safety conveying device. The other power systems, fuel supply systems, waste heat utilization systems, and other systems are completely similar.

三、瓦斯发电投资成效剖析

3、 Analysis of Investment Effectiveness in Gas Power Generation

因低浓度瓦斯不可以储藏,瓦斯气源受限,低瓦斯发电工程规模相对较小,低瓦斯发电机组与高瓦斯发电机组除对气源浓度要求不一样之外,其余各项技术参数根真同样。工程投资主要取决于规模大小、设备选型标准、生产工艺等有关要素。投资1M顺斯发电单位投资额600-1000万元,规模越大,单位投资额越小。高瓦斯发电工程度电瓦斯耗费量立方,低瓦斯发电工程1度电瓦斯耗费量立方,高瓦斯发电效率比低瓦斯发电效率略高。

Due to the inability to store low concentration gas and limited gas sources, the scale of low gas power generation projects is relatively small. Except for different requirements for gas source concentration, the technical parameters of low gas generator sets and high gas generator sets are fundamentally the same. Engineering investment mainly depends on factors such as scale, equipment selection standards, production processes, etc. The investment amount for a 1M Shunsi power generation unit is 6-10 million yuan, and the larger the scale, the smaller the unit investment amount. The gas consumption per kilowatt hour of high gas power generation projects is cubic meters, while the gas consumption per kilowatt hour of low gas power generation projects is cubic meters. The efficiency of high gas power generation is slightly higher than that of low gas power generation.

从投资效益看,低浓度瓦斯价钱元/立方,高浓度瓦斯价钱元/立方。依据元/度电计算,一立方纯瓦斯的发电量是度电,除掉设备保护、人工费、维简投入等元/度电。瓦斯发电效益为元/度电,一个6MWK模的瓦斯电厂,年工作6000小时,年利润=6000*6000*=万元。投资回收期一般为6~12年,瓦斯发电工程依据规模利润状况,投资效益较理想。

From the perspective of investment efficiency, the price of low concentration gas is yuan/cubic meter, and the price of high concentration gas is yuan/cubic meter. According to the calculation of yuan/kWh, the power generation of one cubic meter of pure gas is kWh, excluding equipment protection, labor costs, maintenance inputs, and other yuan/kWh. The benefit of gas power generation is yuan/kWh. A 6MWK gas power plant with an annual working time of 6000 hours and an annual profit of 6000 * 6000 *=10000 yuan. The investment payback period is generally 6-12 years, and gas power generation projects have ideal investment benefits based on their scale and profit situation.

本文由 驰放气发电机组 友情奉献.更多有关的知识请点击 http://www.zhongtuopower.cn/ 真诚的态度.为您提供为全面的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is a friendly contribution from the exhaust gas generator set For more related knowledge, please click http://www.zhongtuopower.cn/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Stay tuned

业务分类

Business classification产品推荐

product recommendation联系方式

Contact Information

截屏,微信识别二维码